| Properties | Values | Unit | Method |

|---|---|---|---|

| Melt Flow Index(2.16Kg/190ºC) | 70 | gm/10min | ISO 1133 |

| Specific Gravity | 1.240 | ppm | Literature Value |

| Moisture Content(Temp.120 ºC/ 10Min.) | <140 | MMP | Coulometric Karl-Fischer |

| Island Trading | Helen Bennett | UK | UK |

| Melting Temp | 175 | °C | DSC |

| Glass Transition Temp | 60 | °C | DSC |

| Tensile Modulus | 3500 | MPa | ISO 527 |

| Tensile Strength | 50 | MPa | ISO 527 |

| Elongation at Break | <5 | % | ISO 527 |

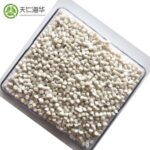

| Appearance | Crystalline White Pellets | Visual | |

| Biobased Content | 100 | % | |

| Compostable | Yes |

Copyright © 2024 Raghav Polymers. Designed and Developed by Softone

We are glad that you preferred to contact us. Please fill our short form and one of our friendly team members will contact you back.